Pressure Sealing Bonnet Forged Globe Valves

Pressure Sealing Forged Globe Valves is designed for high temperature and high pressure according to API600 and ASME B16.34. Compared with bolted bonnet globe valve, the advantage of pressure self-sealing is that the bonnet is sealed under high pressure. The ring will achieve better sealing under its own pressure, so this design is more suitable for high temperature and high pressure working conditions.

The Pressure Sealing Forged Globe Valve not only has its own stable sealing performance, but also the sealing surface adopts iron-based and cobalt-based or tungsten carbide butt welding, which can be used in more severe working conditions

Application standards

- Design and manufacture conform to API 602, BS5352 ,ANSI B16.34;

- Connection ends conform to

- Socket welded dimension conform to ANSI B16.11 , JB/T1751

- Screw ends dimension conform to ANSI B1.20.1 , JB/T7306

- Butt-welded conform to ANSI B 16.25 , JB/T12224

- Flanged ends conform to ANSI B16.5 , JB79

- Test and inspection conform to: API598 , GB/T13927 , JB/T9092

- Structure features:

A threaded and pressure seal bonnet - Materials conform to ANIS/ASTM

- Main materials:

A105 , LF2 , F5 , F11 , F22 , 304(L) , 316(L) , F347 , F321 , F91 , Monel , 20 Alloy

Carbon steel temperature-pressure rate

CL1500 - 3705 P.S.I @ 100oF

CL2500 - 6170 P.S.I @ 100oF

| Part name | A 105/F6a | A105/F6aHFS | LF2/304 | F11/F6aHF | F304(L) 304(L) |

F316(L) 316(L) |

F91 410HF |

|---|---|---|---|---|---|---|---|

| Body | A105 | A105 | LF2 | F11 | F304(L) | F316(L) | F91 |

| Seat | 410 | 410HF | 304 | 410HF | 304(L) | 316(L) | 410HF |

| Wedge | F6a | F6a | F304 | F6aHF | F304(L) | F316(L) | F6aHF |

| Stem | 410 | 410 | 304 | 410 | 304(L) | 316(L) | 410 |

| Bonnet | A105 | A105 | LF2 | F11 | F304(L) | F316(L) | F91 |

| Pin | 410 | 410 | 410 | 410 | 304 | 304 | 410 |

| Gland | 410 | 410 | 304 | 410 | 304 | 316 | 410 |

| Gland eyebolt | B7 | B7 | L7 | B16 | B8(M) | B8(M) | B8 |

| Gland flange | A105 | A105 | LF2 | F11 | F304 | F304 | F91 |

| Hex nut | 2H | 2H | 2H | 2H | 8(M) | 8(M) | 8 |

| Stem nut | 410 | 410 | 410 | 410 | 410 | 410 | 410 |

| Locking nut | 35 | 35 | 35 | 35 | 35 | 35 | 35 |

| Nameplate | AL | AL | AL | AL | AL | AL | AL |

| Handwheel | A197 | A197 | A197 | A197 | A197 | A197 | A190 |

| Lubricaling gasket |

410 | 410 | 410 | 410 | 410 | 410 | 410 |

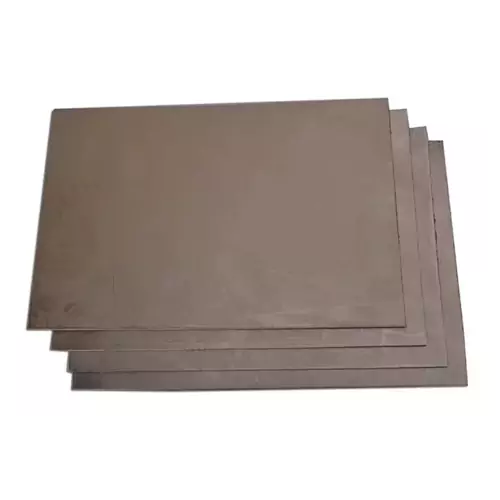

| Packing | Graphite | Graphite | Graphite | Graphite | Graphite | Graphite | Graphite |

| Stop nut | 35 | 35 | 35 | 35 | 35 | 35 | 35 |

| Seal gasket | 420 | 420 | 304 | 304 | 304(L) | 316(L) | 420 |

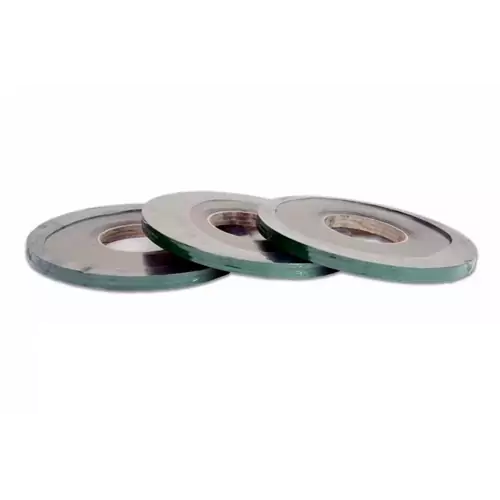

| P.S ring | 304 | 304 | 304 | 304 | 304 | 316 | 316 |

| P.S seat | 420 | 420 | 304 | 304 | 304(L) | 316(L) | F91 |

| Nut pad | 410 | 410 | 410 | 410 | 410 | 410 | 410 |

| Packing nut | Cast steel | Cast steel | Cast steel | Cast steel | Stainless steel | stainless steel | Cast steel |

CL900~CL2500

Dimension of pressure sealing forged globe valve.| Specification (NPS) |

F.P | Class | 3/8 | 1/2 | 3/4 | 1 | 1(1/4) | 1(1/2) | 2 |

|---|---|---|---|---|---|---|---|---|---|

| Face to face | L | CL900-1500 | 140 | 140 | 140 | 140 | 178 | 178 | 216 |

| CL2500 | 186 | 186 | 186 | 186 | 232 | 232 | 279 | ||

| Handwheel diameter |

W | CL900-1500 | 200 | 200 | 200 | 200 | 280 | 280 | 300 |

| CL2500 | 200 | 200 | 200 | 200 | 280 | 280 | 300 | ||

| Height | H | CL900-1500 | 318 | 318 | 318 | 322 | 467 | 468 | 540 |

| CL2500 | 325 | 325 | 325 | 327 | 467 | 468 | 540 | ||

| Flow port dimension |

d | CL900-1500 | 14 | 14 | 14 | 19 | 25 | 30 | 36.5 |

| CL2500 | 14 | 14 | 14 | 19 | 25 | 30 | 36.5 | ||

| Weight(Kg) | CL900-1500 | 11.5 | 11.5 | 10.8 | 10.5 | 19.6 | 21.0 | 55.4 | |

| CL2500 | 12.3 | 12.3 | 11.6 | 10.8 | 26.0 | 28.4 | 60.0 |

REQUEST AN OFFER NOW!

Products List

Low-Emission Forged Gate Valves, Fugitive Emissions Control API624 ValvesRead More

Low-Emission Forged Gate Valves, Fugitive Emissions Control API624 ValvesRead More Low Emission Packing M641Read More

Low Emission Packing M641Read More PackingRead More

PackingRead More Graphite Packing for Cryogenic Fugitive Emissions Control Valves M600S API622Read More

Graphite Packing for Cryogenic Fugitive Emissions Control Valves M600S API622Read More Fugitive Emission Control Packing M600Read More

Fugitive Emission Control Packing M600Read More Graphite PackingRead More

Graphite PackingRead More Graphite PackingRead More

Graphite PackingRead More Graphite PackingRead More

Graphite PackingRead More Graphite PackingRead More

Graphite PackingRead More Flanged GasketRead More

Flanged GasketRead More Graphite GasketRead More

Graphite GasketRead More Graphite GasketRead More

Graphite GasketRead More Flanged Graphite GasketRead More

Flanged Graphite GasketRead More Graphite SheetRead More

Graphite SheetRead More Graphite SheetRead More

Graphite SheetRead More Graphite SheetRead More

Graphite SheetRead More Low Emissions Ball ValvesRead More

Low Emissions Ball ValvesRead More Low Emissions Gate ValvesRead More

Low Emissions Gate ValvesRead More Low Emissions Globe ValvesRead More

Low Emissions Globe ValvesRead More Cast Cryogenic Ball ValveRead More

Cast Cryogenic Ball ValveRead More Forged Cryogenic Globe ValveRead More

Forged Cryogenic Globe ValveRead More Forged Cryogenic Ball ValveRead More

Forged Cryogenic Ball ValveRead More Cast Steel Y Pattern StrainerRead More

Cast Steel Y Pattern StrainerRead More Cast Steel Basket StrainerRead More

Cast Steel Basket StrainerRead More Bellows Sealed Gate ValvesRead More

Bellows Sealed Gate ValvesRead More Forged Bellows Sealed Globe ValvesRead More

Forged Bellows Sealed Globe ValvesRead More Forged Cryogenic Gate ValveRead More

Forged Cryogenic Gate ValveRead More Butterfly Valve of Wafer TypeRead More

Butterfly Valve of Wafer TypeRead More Forged Y Pattern StrainerRead More

Forged Y Pattern StrainerRead More API Butterfly Valve of Lug TypeRead More

API Butterfly Valve of Lug TypeRead More Trunnion Ball ValvesRead More

Trunnion Ball ValvesRead More Orbit Ball ValvesRead More

Orbit Ball ValvesRead More API Floating Ball ValveRead More

API Floating Ball ValveRead More Y-Pattern Forged Check ValveRead More

Y-Pattern Forged Check ValveRead More Forged Check Valves with Flanged or Butt weldedRead More

Forged Check Valves with Flanged or Butt weldedRead More API Cast Steel Wafter Check ValveRead More

API Cast Steel Wafter Check ValveRead More DIN Cast Steel Swing Check ValveRead More

DIN Cast Steel Swing Check ValveRead More DIN Lift Check ValveRead More

DIN Lift Check ValveRead More Forged Swing Check ValveRead More

Forged Swing Check ValveRead More Forged Piston Check ValveRead More

Forged Piston Check ValveRead More API Cast Steel Pressure Seal Globe ValvesRead More

API Cast Steel Pressure Seal Globe ValvesRead More API Cast Steel Swing Check ValveRead More

API Cast Steel Swing Check ValveRead More Cast Steel API Globe ValveRead More

Cast Steel API Globe ValveRead More DIN Cast Steel Globe ValveRead More

DIN Cast Steel Globe ValveRead More Forged Globe Valve With FlangedRead More

Forged Globe Valve With FlangedRead More Forged Y-Pattern Globe ValveRead More

Forged Y-Pattern Globe ValveRead More Welded Bonnet Forged Globe ValvesRead More

Welded Bonnet Forged Globe ValvesRead More DIN Gate ValvesRead More

DIN Gate ValvesRead More Bolted Bonnet Forged Globe ValvesRead More

Bolted Bonnet Forged Globe ValvesRead More DIN Non-rising Stem Gate ValveRead More

DIN Non-rising Stem Gate ValveRead More API Gate ValveRead More

API Gate ValveRead More Pressure Seal Gate ValvesRead More

Pressure Seal Gate ValvesRead More Forged Gate Valve With Flanged EndsRead More

Forged Gate Valve With Flanged EndsRead More Forged Gate Valve With Extended BodyRead More

Forged Gate Valve With Extended BodyRead More Forged Ball Valve of 3 PCRead More

Forged Ball Valve of 3 PCRead More Welded Bonnet Forged Gate ValvesRead More

Welded Bonnet Forged Gate ValvesRead More Forged Ball Valve of 2 PCRead More

Forged Ball Valve of 2 PCRead More Pressure Sealing Forged Gate ValveRead More

Pressure Sealing Forged Gate ValveRead More Bolted Bonnet Forged Gate ValvesRead More

Bolted Bonnet Forged Gate ValvesRead More